Contact Us

Tel:

+86-19953440703

E-mail:

sales@tangchaotech.com

WhatsApp:

+86-15053441710

Address:

Shandong Province Dezhou City Decheng District Xinhu Street Office Jiefangzhong University Dezhou Lufeng Miramar Hotel Management Co., Ltd.

Reverse Osmosis Equipment 3 tons

After several years' development,our products include screws, bolts, nuts and anchors. Over 95% of our products are exported to the overseas market, such as Europe. America and Southeast Asia.

- Commodity name: Reverse Osmosis Equipment 3 tons

- Description

-

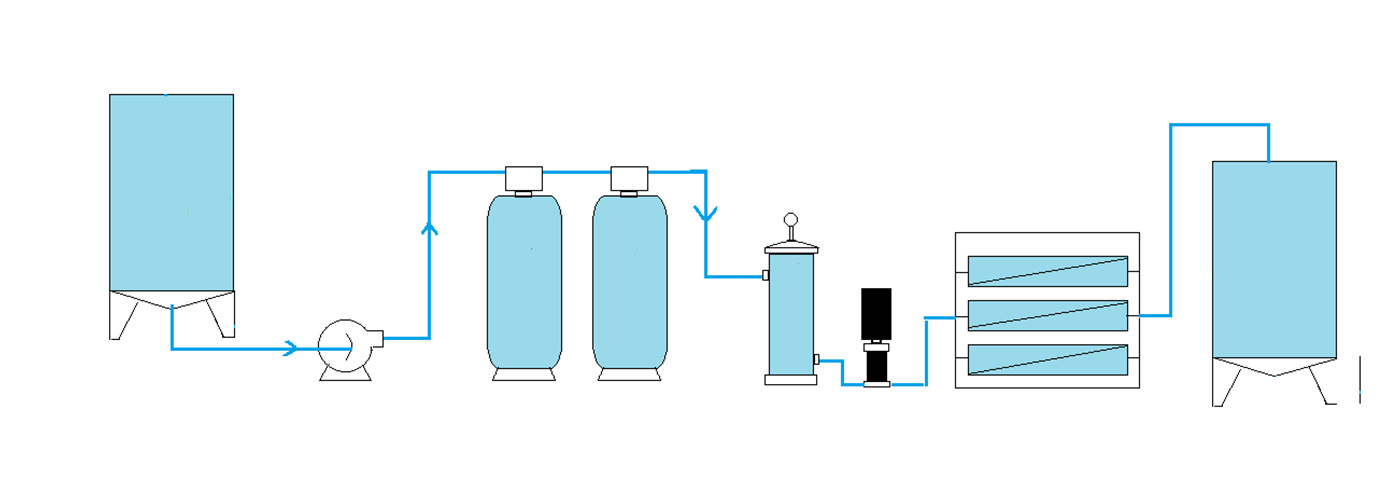

Process flow chart

Reverse osmosis technology is a modern high technology developed recently in China. Reverse osmosis is to separate water from solution after it permeates the specially-made semi-transparent membrane through exerting a pressure that is higher than the osmosis pressure on the solution. As this process is reverse to the natural permeation direction, it is called reverse osmosis. According to different osmosis pressures of various materials, the process of reverse osmosis with a pressure higher than the osmosis pressure can be used to reach the purposes of separation, extraction, purification and concentration of a certain solution. It does not need heating and there is no phase changing process. Therefore, it saves more energy than traditional process.

Working principle

●This system occupy little space, easy to operate, wide application.

●When used for disposing industrial water, the reverse osmosis device does not consume large amounts of acids and alkalis, and there is no secondary pollution. In addition, its operation cost is also low.

●Reverse osmosis desalting rate 98%,98% of organic matters,colloids and bacteria can be removed.

●Finished water under good electric conductivity,one stage 10us/cm,two stage around 2-3us/cm, EDI≤0.5us/cm (raw water≤300us/cm).

●High operation automation degree. No need for manual supervision. The machine will automatically stop in case of water sufficiency and automatically start in case of no water. Timed flushing of front filtering materials by automatic controller. Online display of conductivity of raw water and pure water.Equipment Technology

▲Raw water tank and booster pump’s main functions: constant system water supply pressure and stable water supply volume.

▲Multi-media filter: also known as quartz sand filter, using the multiple filter layer, the main purpose is to remove the sediment, rust, colloidal substances, suspended matter and other particles more than 20um of substances in the raw water. The system can do backflushing, positive flushing, such as a series of operations. Main functions: ensure the filtered water quality of the equipment and extend the working life of the equipment.

▲Activated carbon filter: Using fruit shell activated carbon, it can not only adsorb electrolyte ions, but also remove pigments, odors, a large amount of biochemical organic matter in water, reduce residual chlorine value, pesticide pollutants and trihalides. The system can do back flushing, positive flushing, such as a series of operations. Main functions: ensure the filtered water quality of the equipment and extend the working life of the equipment.

▲Automatic dosing and scale inhibition device or ion exchanger (optional): Effectively control inorganic scaling within a large concentration range, prevent the formation of insoluble substances with iron aluminum oxides and silicon compounds, prevent scaling on the reverse osmosis membrane surface, improve water production and quality and reduce operating cost.

▲Security filter: A 5um filter element is used to trap a small amount of mechanical impurities that have leaked through the pre-treatment system. The filter cylinder adopts SUS304 material and is equipped with PPF filter elements inside. This filter element is a deep filtration element with high efficiency and low resistance. Suitable for further purification of water with low suspended impurities (turbidity less than 5 degrees). Main function: ensure that the water particle size entering the reverse osmosis membrane is less than 5um.

▲High-pressure pump: Because the reverse osmosis membrane requires high pressure during operation, the high-pressure pump is the main operating equipment of the reverse osmosis system, providing a power source for the operation of the reverse osmosis device. Low pressure and high pressure protection switches are installed at the inlet and outlet of the high-pressure pump. When the inlet pressure is lower than the set value of 0.05Mpa, the high-pressure pump stops to prevent damage caused by the pump being emptied; When the inlet pressure is higher than the set value (1.5Mpa),the high-pressure pump stops to protect the high-pressure pump and membrane components from damage.

▲Reverse Osmosis System: By pressurizing with a pump, a reverse osmosis membrane with a pore size of 1/10000um is used to convert high concentration water into water of any concentration, while isolating all impurities such as industrial pollutants, heavy metals, bacteria, viruses, etc. that enter the water, thereby achieving the physical and chemical indicators and hygiene standards specified for purified water. Due to reverse osmosis technology, the water purity produced is currently the highest among all water production technologies mastered by humans, with a cleanliness level of almost 100%.

Technical Parameters

Water inlet pressure 0.3MPA Desalination rate 98% Operating pressure 0.5MPA-1.5MPA Recovery rate 50%-75% Operating temperature 5℃-45℃ Water output Design according to the actual situation of the customer

Key words:

ANCHOR | BOLT | SCREW | NUT | BAND | BRACKET | ROD | OTHER FASTENER | NON-STANDARD

Packing And Delivery

Application Areas

Hotel water usage

Beer brewing

Agricultural planting

Breeding industry

Laboratory water

Textile industry

Chemical industry

Power plant industry

Customer Visit

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!